The Unsung Hero Keeping Your Car Dry in Rain: Demystifying EPDM – The “Long-Life Rubber” Powering the Auto Industry

2025/07/10

1. What is EPDM Rubber?

Chemical Identity:

EPDM is a polymer synthesized by copolymerizing ethylene (E), propylene (P), and a small amount of diene monomer (D). Its unique “ternary” structure delivers dual advantages:

Ethylene + Propylene: Forms a backbone resistant to aging and chemical corrosion

Diene Monomer: Introduces crosslinking sites for vulcanization and elasticity

Core Performance Highlights:

Weather Resistance King: Withstands UV rays, ozone, and extreme temperatures (-50°C to 150°C)

Anti-Aging Expert: Service life of 20-30 years

Sealing Guardian: Low gas permeability, high resilience

Eco Champion: Non-toxic, odorless, and recyclable

2. Where You Encounter EPDM Daily

Scenario 1: Automotive Industry’s “Sealing Specialist”

Window Seals: Core barrier against water, noise, and dust

Engine Systems: Coolant hoses and turbocharger pipes (high-temp resistance)

EV Battery Packs: Waterproof seals for high-voltage safety

Sunroof Tracks: UV resistance for decade-long performance

Data: Average car uses 12kg of EPDM, accounting for >40% of all rubber components

Scenario 2: Construction Sector’s “Climate Shield”

Roofing Membranes: Core material for single-ply roofing systems (30-year lifespan)

Curtain Wall Gaskets: Resists wind pressure and thermal expansion

Underground Seals: Ultimate defense against groundwater infiltration

Scenario 3: Household’s “Silent Partner”

Appliance Seals: Washing machine doors, refrigerator gaskets

Sports Surfaces: Eco-friendly track granules

Children’s Toys: Safe elastic components

3. EPDM Evolution: From Basics to Smart Formulations

①Nanotechnology Enhancement

Nanoclay/silica additives increase strength by 50% and double abrasion resistance (used in Tesla Model Y battery seals).

②Green Revolution

Bio-based EPDM: DuPont’s 30% plant-derived monomers

Halogen-Free Flame Retardants: Meets EU RoHS 2.0 standards

Closed-Loop Recycling: Michelin achieves 100% recycled seals

③Smart-Response EPDM

Lab-developed “self-healing EPDM”: Microcapsules release repair agents when damaged (future potential for spacecraft seals).

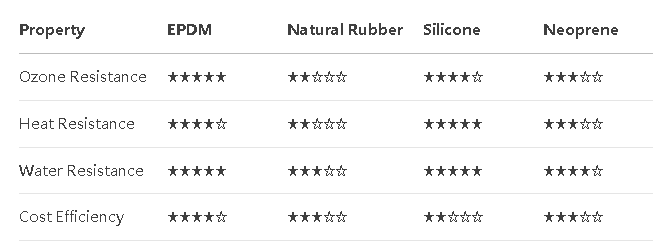

4. EPDM vs. Other Rubbers: Performance Showdown

Note: EPDM wins overall for weather resistance and value, making it the top choice for outdoor seals

5. Industry Trends: EVs Fueling EPDM Innovation

Electric vehicle growth drives EPDM advancements:

High-Voltage Sealing: Battery packs require 1000V+ resistant seals

Lightweighting: Foamed EPDM density reduced to 0.6g/cm³ (vs. 1.2g/cm³ standard)

Coolant Corrosion Resistance: New glycol coolants accelerate rubber aging

Market Forecast: Global automotive EPDM market to exceed $8 billion by 2025 (Grand View Research)

6. Cool Facts: EPDM’s “Impossible Missions”

Spacecraft Seals: ISS window seals maintain integrity for 20+ years

Undersea Tunnels: Hong Kong-Zhuhai-Macao Bridge joints designed for 120-year service

Polar Exploration: Core material for -60°C Antarctic station seals

Conclusion: The Sustainable Future of an Understated Champion

Over half a century, EPDM has proven true technology lies not in visibility but in reliably solving real-world problems. As global manufacturing turns green, EPDM’s recyclability and longevity make it vital for the circular economy. Next-gen functional EPDM will push performance boundaries, continuing to guard everything from daily life to outer space.